PRODUCT DESCRIPTION

The vertical electric oven performs the following heat treatments:

- heating for tempering purposes

- heating for the high and medium return,

- heating for detensioning,

- cementing for cast iron alloys and non-ferrous alloys.

The oven is made on a metallic structure, properly dimensioned so that it can be self-sustaining and take over the loads that occur during the operation.

The range of mining products for which thermal treatment is required: trees with max. Ø 350 x 1900 mm, bits, different size bolts, rods, runners, etc.

CONDITIONS IN WHICH THE OVEN WORKS

- intensively polluted with dust, nox;

-regional industrial hall operation

TECHNICAL SPECIFICATIONS

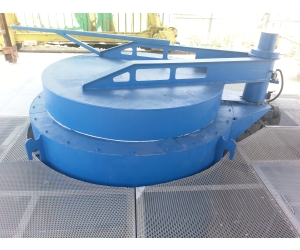

The oven type is vertical, with electric heating, being designed for the thermal treatment of tempering, returning, cementing and straining.

The door of the oven is of the manually operated lid type, performing a lifting and translation movement.

The heater is electrically heated, the heater elements being located on the side wall of the oven.

The heating elements are arranged on ceramic supports.

The oven housing is made of a welded steel plate structure of min. 8 mm, protected by primer coating and temperature resistant paint.

Insulation ovens is made of ceramic fiber mats and mattresses. This solution offers the advantage of having a significantly reduced thermal insulation. Under these conditions the heating efficiency increases as a significant reduction of the total heating mass is obtained, relative to the useful load in the oven. The insulation solution with ceramic fiber products is a modern solution, with an exceptional energy efficiency, while providing a technical solution according to the environmental requirements by removing asbestos-based compounds.

Useful dimensions of the oven:

- diameter: Ø1000 mm

- adjustment: 2000 mm

- Window duty rate: 800 mm

- Heating mode: electric;

- Net Load Weight: 1500 Kg;

- Installed power for oven heating: ≥ 100 Kw;

- Supply voltage: 3x400 V

- Accuracy of temperature control maintained at ± 5 ° C;

- Digital temperature indication with resolution of 1 ° C;

The oven will be equipped with microprocessor temperature controllers with the possibility of programming any temperature chart.

The oven will be divided into several zones, each area being equipped with a temperature control system and over-temperature protection.

The oven will have acoustic and optical warning signals of different states;

Protection against operation outside normal parameters;

-failure of the thermocouple;

-at overtemperature;

-when opening the malfunctioning cover of the electrical system;